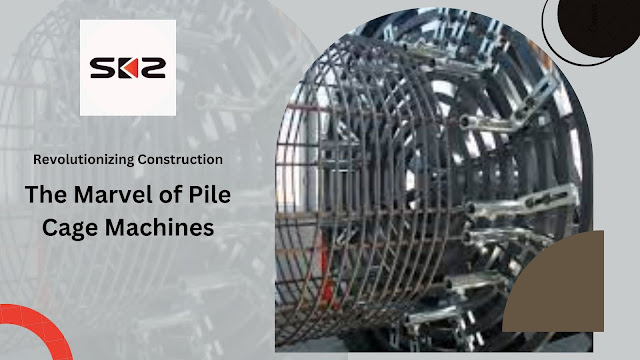

Revolutionizing Construction: The Marvel of Pile Cage Machines

In the realm of construction technology, innovation is the cornerstone of progress. One such innovation that has been making waves in the construction industry is the pile cage machine. This remarkable piece of machinery has revolutionized the way deep foundation elements are fabricated, leading to increased efficiency, enhanced safety, and remarkable cost savings.

In this blog, we delve into the world of pile cage machines, exploring their functionality, benefits, and the impact they've had on construction projects worldwide.

The Foundation of Innovation: What is a Pile Cage Machine?

Pile cage machines, also known as rebar cage machines, are specialized construction equipment designed to automate the process of creating reinforced concrete cages for deep foundation elements like piles and diaphragm walls. These cages consist of a precisely arranged network of steel reinforcement bars (rebars) that provide structural integrity to the foundation element. Traditionally, assembling these cages was a labor-intensive task, demanding skilled labor and substantial time investments. Pile cage machines have redefined this process by automating the fabrication of these cages, reducing human error, and significantly accelerating the construction timeline.

How Pile Cage Machines Work: The Inner Mechanism

At its core, a pile cage machine is a sophisticated piece of engineering. It comprises a robust framework, a rebar feeding system, a bending mechanism, and a welding station. The process begins with feeding individual rebars into the machine, which are then bent and shaped according to the design specifications. The machine's intricate software ensures precise bending angles and lengths, adhering to the engineering requirements. Once the rebars are shaped, they are welded together to form the cage's skeletal structure. The end result is a meticulously crafted cage that conforms to the exact dimensions and reinforcement patterns needed for the foundation element.

Advantages that Transcend: Benefits of Pile Cage Machines

The adoption of pile cage machines brings forth a multitude of benefits that resonate throughout the construction industry.

Enhanced Efficiency: Pile cage machines drastically reduce the time required to fabricate reinforcement cages. What once took hours or even days can now be accomplished in a matter of minutes. This not only accelerates construction schedules but also enables project teams to meet tight deadlines with ease.

Precision Personified: Human error is an inherent risk in manual cage assembly. Pile cage machines eliminate this concern by ensuring consistent precision in bending angles, lengths, and welding. The result is a reliable and uniform product that meets the highest engineering standards.

Elevated Safety Standards: Construction sites are inherently hazardous. By automating the cage fabrication process, workers are exposed to fewer risks associated with manual bending and welding of rebars. This shift promotes a safer working environment and reduces the occurrence of workplace accidents.

Cost Efficiency: While the initial investment in pile cage machines may seem substantial, the long-term cost savings are noteworthy. The reduction in labor costs, coupled with accelerated project timelines, translates to significant financial gains over time.

Flexibility and Customization: Pile cage machines are adaptable to various rebar sizes and cage configurations. This flexibility allows construction professionals to tailor their designs to project-specific requirements without compromising efficiency.

Eco-Friendly Construction: Efficient resource utilization is a priority in contemporary construction. Pile cage machines contribute to this goal by minimizing material wastage and energy consumption during the cage fabrication process.

Transforming Construction Landscapes: Real-world Impact

The impact of pile cage machines on construction projects worldwide cannot be understated. Major infrastructure endeavors, such as skyscrapers, bridges, and deep foundations for critical structures, have benefited immensely from the efficiency and precision these machines offer. The reduction in project durations has enabled governments, developers, and contractors to deliver projects on time or ahead of schedule, fostering economic growth and development.

Furthermore, the integration of technology like Building Information Modeling (BIM) with pile cage machines has augmented the accuracy of cage fabrication. This synergy between digital design and automated fabrication streamlines the construction process, resulting in flawless execution of complex designs.

Conclusion: Pile cage machines exemplify the transformative power of technology in the construction industry. Their ability to enhance efficiency, ensure precision, elevate safety, and promote sustainable practices makes them an indispensable asset in modern construction. As the industry continues to evolve, one thing remains clear: innovations like pile cage machines are shaping the skylines of tomorrow and laying the foundation for a more efficient and advanced future.

For More Information on pile cager machines visit us: www.skzmachinery.com

Comments

Post a Comment